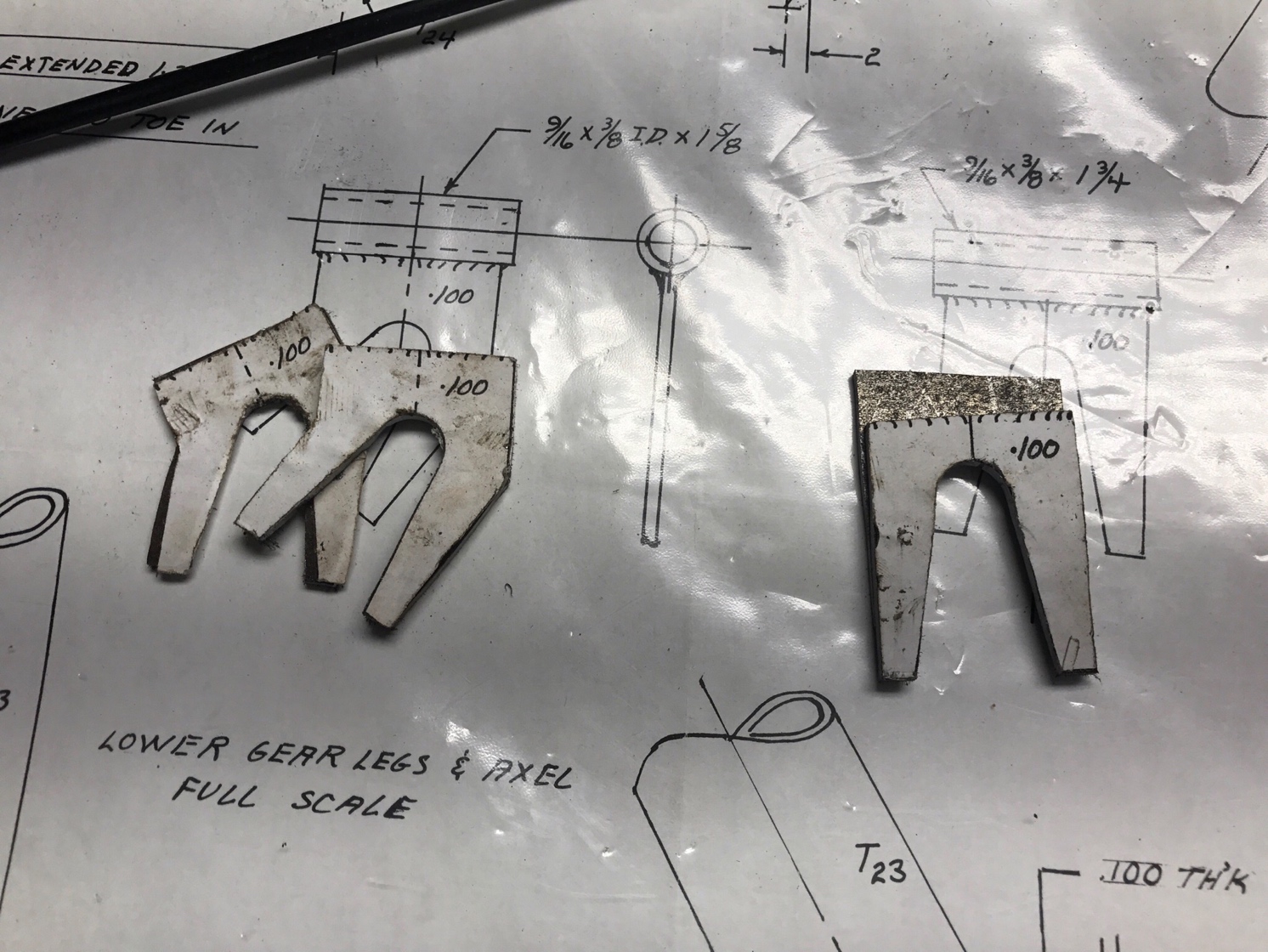

Began making the parts for the landing gear. Cut the .100 steel reinforcements for the gear leg attach points on the band saw and cleaned up with the mini belt sander.

Measured my attach fittings on the fuselage then cut the 9/16 tubing to fit. Welded the heavy wall tubing to the .100 steel reinforcement pieces.

Steve threaded my 1.5″ x .120 axles and turned them down a couple thousands to 1.498 so they fit real good with the Cleveland wheels I purchased.

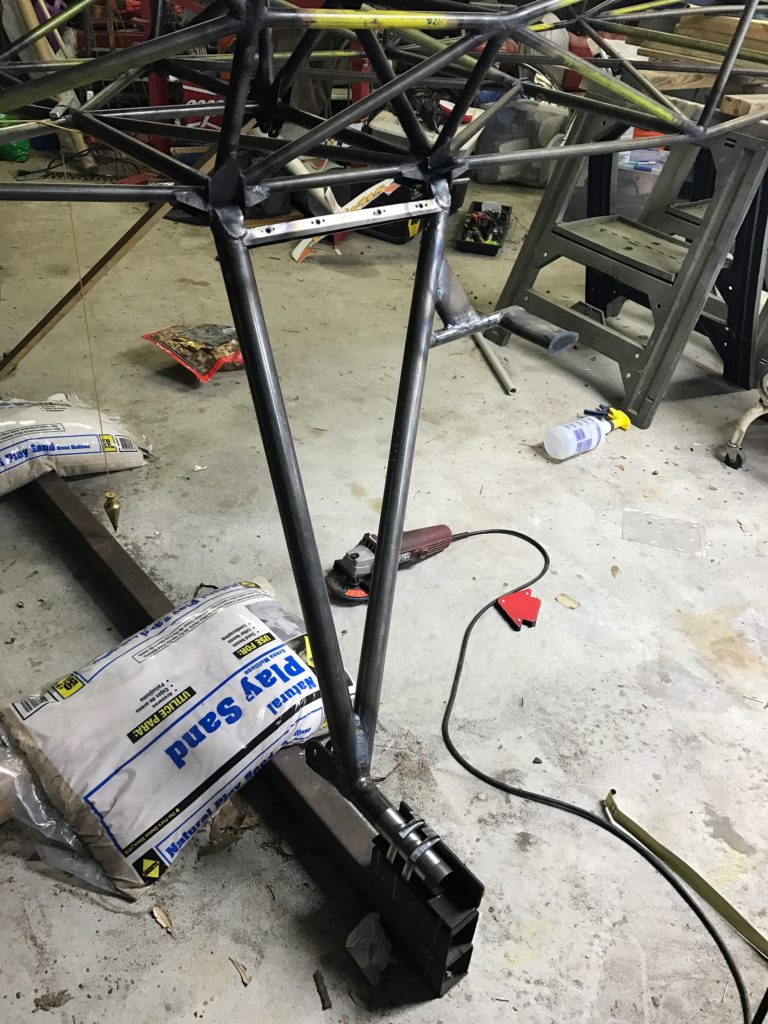

Got the fuselage height set and leveled in both directions. I threw together a stand with a couple adjustable 3/8 rods to help get everything level. It’s not pretty but it’s fairly stable and works.

Dropped a plumb bob from the center of the front gear attach to the floor and marked. Marked 2″ forward and will lay out the axle jig next.

11/10/2016

Marked the floor for the axle jig, centered it up on the fuselage and shimmed the jig level. Marked the tread center on the axle and also where the center of the front gear leg tube should meet the axle. Set the axles in the jig at the right distance then measured from the tailpost to each axle to double check everything is squared up.

Fuselage Leveled laterally.

Axle jig from Steve, all set up.

11/11/2016

Getting the legs cut and fit. Cut the notch in the top to accept the attach fitting then fishmouth the tubes where they meet. I use a free online tool to print out fishmouth patterns which typically get you very close. I then use my angle grinder with a flap disc to fine tune the fit.

First leg cut.

I am a big fan of the fishmouth templates. Maybe one day I will be good enough to eyeball.

Pretty close, now I fine tune with the angle grinder.

The rear gear legs get a small angle section. I was generous on the length and cut to the proper length after welding.

11/13/2016

Got the pilot’s side tacked.

11/15/2016

Got the top channel welded in. Drilled for nutplates to hold fairing later on.

Reinforcement pieces welded on over the attach bushing. I put heavy tacks on one side then used a torch and hammer to bend it across the top.

11/17/2016

Trimmed the inside portion of the axle to plan then inserted a piece of .120 wall tubing per the engineering notice. This is supposed to beef up the axle. I used sleeve retainer to “glue” it in and the shock strut attach bracket welding will catch the end of it too.

End view. That ugly welding is not final……

12/1/2016

Worked on the passenger side gear leg the last few days. Both gear are final welded and shock strut attach bracket along with the reinforcement pieces are on. Began building a boarding step on the pilot’s side.

Discussion

Comments are closed.