I was able to get the right wing aieleron hinged, pocket skins drilled and fitted as well as trimming the wing skins. I followed the same process as the left wing, and there weren’t too many surprises.

After everything is fitted, sleeve retainer glue is used to glue the heim joints into the hinge mount…..then left to dry for 24 hours.

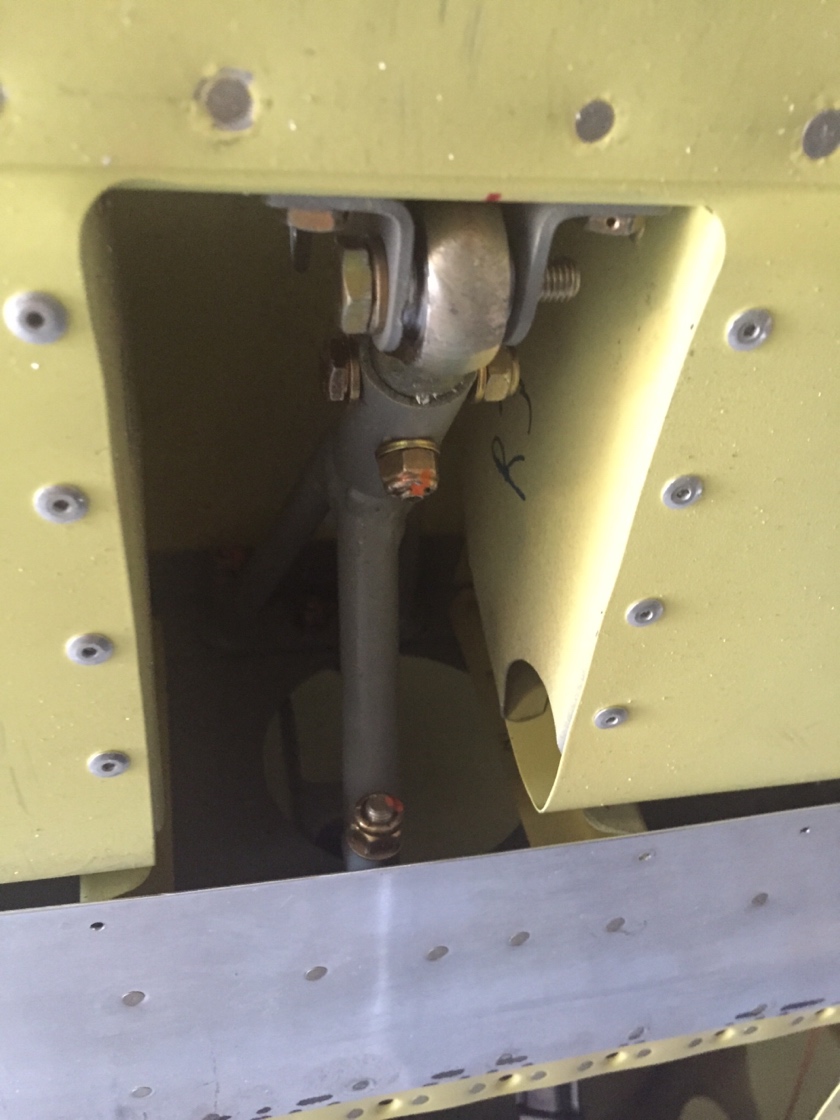

the hiem joint is retained by 2 bolts after the glue sets up. The orange torque seal tells me i have final torqued the bolt as well as serve as a visual indicator if a nut moves.

Just need to fit the .032 skin at the root and tip and that will wrap up most of the skinning and assembly work. Still need to fit the fuel tanks into the right wing and finish the plumbing.

I did end up replacing a couple of bolts on the right wing to get better length. There are supposed to be from 1 to 4 threads visable to meet the FAA requirements.

Discussion

Comments are closed.