I’ve never done much composite work except for some minor boat repairs over the years, but I want to try and make a set of Hoerner style wingtips for my Bearhawk vs. the rounded style that are commercially available. I want to put some LED landing lights in each tip, so I might as well try making the whole thing.

I am going to start with 3 layers of 8 oz. Bi-directional cloth and see if that is enough, adding more as neccasary. I will be using Silvertip laminating resin. The plan is to build 2 airfoil forms then hotwire the basic airfoil shape from polystyrene foam purchased from Lowes. From there I will hotwire the Hoerner shape and hand shape the rest of the curvature by eye. All of this is based on a couple of videos I saw on youtube by Jeff while he was building wingtips for his Soneri

I set the left wing on my worktable and detached the outer support frame. My wings are in racks and attached on both ends, so it was a bit of wrangling to get full access to the tips. Once I had the tip end clear, i put my piece of MDF up against the tip and traced the airfoil. The little divet holes you see are to give clearance to the support angle I have on my wingtip…..where the rack attaches.

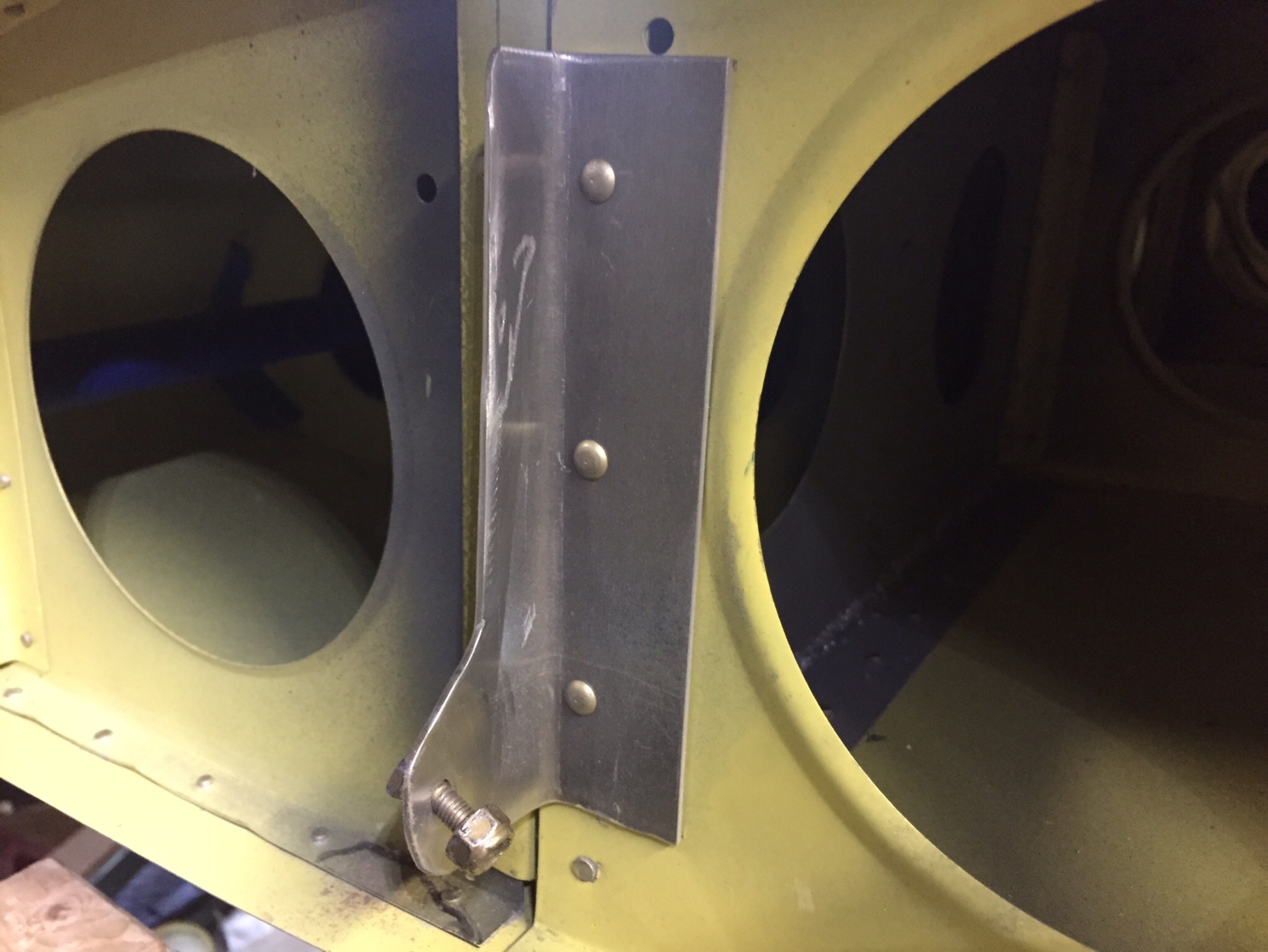

How my rack attaches at the wingtip.

I rough cut the MDF based on my tracing then sanded until the line was gone. I want to take another .05-1/16 off around the form to allow for the layup thickness. I made a little offset tool from a tounge depressor and made a guide line. My next step will be to sand down to this line.

Got the master form sanded down 1/16 all the way around. I then used a flush trim router bit to make a copy of it. I’ve now got the 2 identical forms I need to sandwich the foam between to hotwire.

Rough cut 5 pieces of 2″ foam that I will glue together to get a combined thickness of 10″.

Discussion

Comments are closed.